Advancements in Medical 3D Printing

Three-dimensional (3D) printing has been around since the 1980s, when Chuck Hull patented the mechanical process of printing successive layers of material to create objects. Known as stereolithography or additive manufacturing, the process quickly spread beyond industry into a number of sectors, including medicine.

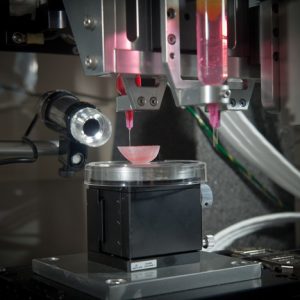

A 3D printer is similar to a standard computer printer except that, instead of ink, liquid plastic, metal, polyvinyl alcohol, and other materials flow through its print nozzles. 3D printers are unique in that the process can create three-dimensional solid-state objects made from a variety of materials. Printed objects can be as simple or as intricate as needed by the designer without requiring extra steps in the manufacturing process.

A 3D printer is similar to a standard computer printer except that, instead of ink, liquid plastic, metal, polyvinyl alcohol, and other materials flow through its print nozzles. 3D printers are unique in that the process can create three-dimensional solid-state objects made from a variety of materials. Printed objects can be as simple or as intricate as needed by the designer without requiring extra steps in the manufacturing process.

In 1999, surgeons grew a human bladder by layering human bladder cells onto 3D printed scaffold then later transplanted the bladder into the patient that donated the cells. In 2002, scientists used bio-ink replicating kidney tissue to print a functioning kidney.

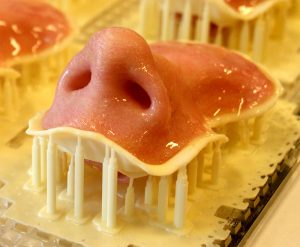

There have been several major advancements since the earliest days of medical 3D printing. While it is still not possible to print out an entire organ suitable for transplant, it is possible to use three-dimensional printing to create scaffold for growing organs, grow tissues for laboratory testing, make skin grafts for burn victims, print sheets of cardiac tissue that beats like a heart, and more.

State of the Art Medical 3D Printing

Scientists from Harvard University recently made the first 3D printed organ-on-a-chip with integrated sensing, which allows researchers to collect reliable data during laboratory studies. These organs-on-chips, also known as  microphysiological systems, closely match the properties of a specific disease or individual patient cells suitable for use in the laboratory. These chips simplify data acquisition and allow researchers to change and customize the study design system, opening new avenues for in vitro tissue engineering, toxicology and drug screening research.

microphysiological systems, closely match the properties of a specific disease or individual patient cells suitable for use in the laboratory. These chips simplify data acquisition and allow researchers to change and customize the study design system, opening new avenues for in vitro tissue engineering, toxicology and drug screening research.

Other researchers use direct laser writing to shape and form 3D printed undifferentiated stem cells to create complex 3D structures for various biomedical applications. Another company recently released a realistic-feeling 3D printed arm modelstudents can use to learn how to suture skin. The company, San Draw, had previously released a 3D printed arm model suitable for practicing injections. The 3D printed skin simulates the anatomy and feel of real human skin to improve student training.

3D printing presents nearly unlimited potential in the production of surgical instruments, including forceps, hemostats, scalpel handles, clamps, and even surgical smoke evacuators. 3D printed surgical tools come out of the  printer completely sterile and ready to use, saving both time and money in sterilization, packaging and storage. Printed tools also cost one-tenth as much as stainless steel tools. 3D printing could therefore boost surgery access in low-income areas and reduce the risk of infection in areas with limited access to sterilizers.

printer completely sterile and ready to use, saving both time and money in sterilization, packaging and storage. Printed tools also cost one-tenth as much as stainless steel tools. 3D printing could therefore boost surgery access in low-income areas and reduce the risk of infection in areas with limited access to sterilizers.

Researchers can print out and expose various body tissues to chemicals and other substances to study the reaction of toxins on healthy tissue. Now scientists can print out cancer cells and other types of disease cells to study how tumors grow and develop, and to evaluate the effects of various treatments on those printed cells.

Research and development of medical 3D printing will likely accelerate as scientists find new uses for the additive manufacturing process and manufacturers learn new techniques for making medical and surgical products. 3D printers will certainly become more commonplace in the surgical suite and in laboratories in the coming years.

Source

https://3dprintingindustry.com/3d-printing-basics-free-beginners-guide/history/

http://www.nature.com/nmat/journal/vaop/ncurrent/full/nmat4782.html

https://www.researchgate.net/publication/309393081_3D_microfabrication_of_complex_structures_for_biomedical_applications_via_combination_of_subtractiveadditive_direct_laser_writing_and_3D_printing

https://3dprint.com/152558/san-draw-medical-suture-training/

https://3dprint.com/6652/3d-print-medical-tools/

Frank Magliochetti is Managing Partner for Parcae Capital.

-

North Andover, Massachusetts

This column of posts is directed at the Healthcare Industry. Frank plans to release a new site dedicated to the industry. He currently assists companies who are building, restructuring, transforming and resurrecting there business’s. An example of his client base are, Xenetic Biosciences , IPC Medical Corp, Just Fellowship Corp, Environmental Services Inc., Parsons Post House LLC, ClickStream Corporation as well as having a business talk radio show; The Business Architect on the URBN network.